|

Supertune the EQ6 -Addendum

| Supertuning the Synta / Skywatcher EQ6 / Orion Atlas |

This procedure is an addendum to the main strip down guide located HERE and will guide you towards Super-tuning the mount to get better results. This guide needs to be read in conjunction with the main strip down guide and shows how to get better tuning with the RA and DEC worm gears by using additional shims to set the worm gear to worm roller more accurately.

This guide also includes a shim calculator so you can automatically calculate the shim sizes required when rebuilding.

Notes:

I am going to break with convention for super-tuning in this guide and NOT replace the main bearings. Much discussion about these has taken place in various guides and forums but the fact is the main bearings are perfectly adequately engineered for a mount like the EQ6. The only bearings I changed in this guide were worm roller end shaft bearings because these are generally pretty poor quality from the factory. The other bearings are more than adequate as the mount does not need high speed bearings and ceramic bearings are prone to potential problems in cold weather.

The super-tuning element is concerned with the setting of more accurate worm gear alignment. Its assumed if you are carrying out this process you will have carried out all steps for improving the mount in the strip down and rebuild guide with regards to cleaning and de-burring components and replacing the factory lubricant with a lithium type grease.

The EQ6 mount used for this guide was a new model and was probably manufactured around 2009. The overall machining was far better than on the earlier mount used for the strip down guide and engineering tolerances were significantly better. The mount showed a better quality lubrication although it was almost dry in places and a generally ‘cleaner’ level of engineering with none of the swarf and drek found in the earlier generation Synta mounts I have disassembled.

Replacement parts required for this guide:

The only parts acquired for this guide were the worm roller end shaft bearings and some additional shims. Details of these are as follows along with a complete bearing list if you find any of your bearings have been damaged or are unfit for use.

Shims

Pack of Delrin shims in assorted sizes. These can be acquired from;

![]()

Bearings

These are fairly standard bearings and can be acquired almost anywhere. Mine were acquired from ebay relatively cheaply. A complete list is supplied for your information although for tuning only the worm roller end shaft bearings are worth replacing in my opinion. There are very many manufacturers of bearings, SKF bearings are relatively common in the market place and these were used. Other manufacturers part codes may differ slightly – if in doubt check with your supplier.

| QTY | Application | Manufacturer | SKF Product Code | Replaced in this Guide |

|---|---|---|---|---|

| 4 | Worm Roller End Shaft Bearings |

SKF | 608 2RSH | YES |

| 6 | Main Shaft Bearings (3 per axis) |

SKF | 6008 2RSH (Equivalent 6008 2RS1) | NO |

| 1 | DEC Shaft Taper Bearing |

SKF | 30206 J2/Q | NO |

| 1 | RA Shaft Taper Bearing |

SKF | 32208 J2/Q | NO |

Tools required for this guide:

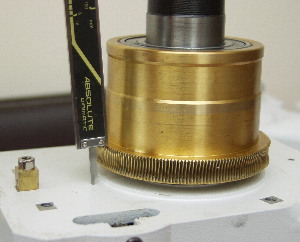

In addition to the tools required to do the mount strip down for supertuning you will also require the use of a digital caliper. These can be acquired readily at reasonable prices from sources such as Amazon from around £10 upwards.

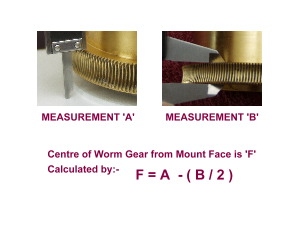

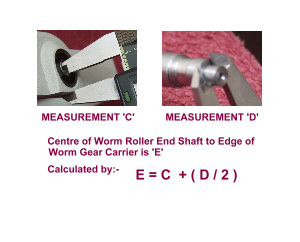

| Shim Setting/Calculations |

Note: These are supplied un-lubricated so require the seals to be gently pried away with a very thin screwdriver and the bearing to be lubricated with the lithium grease before replacing the seals.

You can however simply enter your measurements into the calculator on this page and it will carry out the shim size calculation for you.

You can however simply enter your measurements into the calculator on this page and it will carry out the shim size calculation for you.

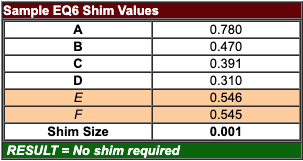

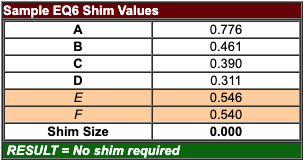

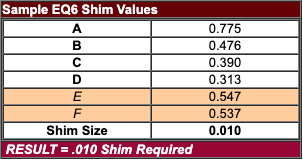

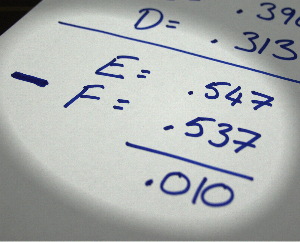

Note: Sample data from 2 other EQ6 Mounts is given in the tables below to give you some idea of what sorts of numbers you should be seeing.

All of these calculations are done for you by just entering your A, B, C and D measurements into the following table

Enter your A, B, C, D measurements into this table to calculate the correct shim to place between the worm gear and the bearing face. Note: When you click SUBMIT the page will reload and you will need to scroll down to the table to see the result.

Note: If the original teflon washer from the factory is badly worn you can replace it with a similar sized washer OR simply carry out your measurements with NO washer in place and then use the appropriate sized Delrin shim washer from the measurements and calculations

Observations:

The EQ6 used to create this guide actually needed no shims applied to the RA axis as it was perfectly well set-up, the large amount of play in the RA axis was tuned out just through a rebuild and relubrication and careful setting of the worm gear during the worm tuning stage.

The DEC axis however was rather challenging and this is described with pictures below…..

|

What this problem indicated to me was that to some extent these mounts need a sympathetic tune rather than a strictly scientific one. It can often be an art more than a science and requires a certain ‘feel’ to weigh up whether a shim is too much or too little. If you are facing this kind of problem after supertuning read the shim washer considerations at the end of the EQ6 Case Study HERE The mount used in this guide was over time tuned to a much higher degree than when it left the factory and after the stages described in the EQ6 strip down and rebuild guide and the supertune guide it operates far more quietly with no play in either axis. |

| Thanks My thanks to all the people who have encouraged me to create this guide and who have offered help and support in the making of this guide. You know who you are and you have my gratitude. |