|

Strip Down and Cleaning of the Right Ascension Axis

| Synta EQ6 / Orion Atlas – Stripping & Cleaning the Right Ascension (RA Axis) |

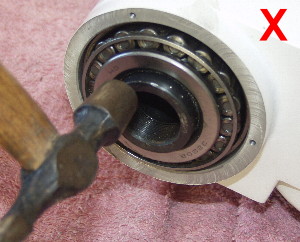

To carry out this procedure you will need a good assortment of tools including cross head and Phillips screwdrivers, a rubber or nylon mallet, a soft toothbrush,

degreasing agent, metric Allen keys, long nosed pliers, lots of lint free cloths and lithium grease.

I found commercial degreasing agents somewhat ineffective and resorted to using good old hot soapy water. Lithium grease is easily available from shops

selling bicycles. It’s also advised to have a large soft towel or similar to lay the mount on while working on it to protect its external finish.

I would strongly advise you do not attempt this procedure without reading it through a few times in advance to understand the process. The procedure takes

around 4 hours from top to bottom (but read the observations at the bottom of this page) unless you are very confident of what you are doing and have exactly

the right tools.

Its definitely best to have someone around to help you with some elements of it – remember take your time and when in doubt STOP and THINK.

Take a break when tired because you don’t want to bodge anything.

The DEC and RA worm gear adjustment process required after re-assembly can be quite lengthy as its very much trial and error so bear this in mind before

starting and allow plenty of time to carry out the procedure – it will pay dividends in terms of smooth and precise running and longevity of the mount.

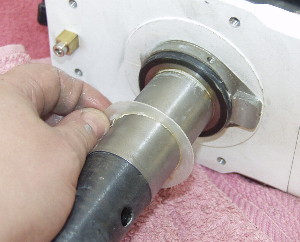

| Stage 1 – Stripping the RA Axis |

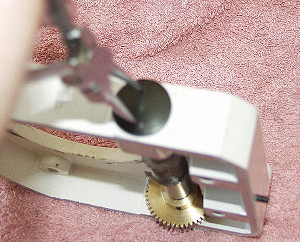

| Stage 2 – Stripping the Worm Carrier |

| Stage 3 – Cleaning & Lubrication |

With a clean lint free cloth wipe all of the oil from the components. On this mount the roller bearings

With a clean lint free cloth wipe all of the oil from the components. On this mount the roller bearings

were sealed and appeared to be well lubricated so were left alone. The tapered bearing had almost no

lubrication and so was cleaned and relubricated with lithium grease.

To lubricate bearings put a blob of grease onto the palm of your hand and press the bearing into it and

then rotate the bearings around forcing the grease into the inside of the bearing.

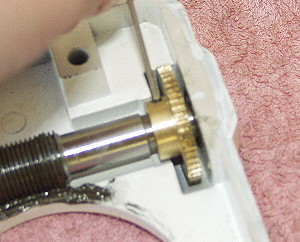

The brass worm gears and steel worm along with the carrier should all be cleaned in a degreasing agent. I personally find really hot water and a basic detergent works best. These were cleaned with a soft toothbrush and the rinsed and left to dry. All of the gears showed either little lubrication and/or engineering swarf present.

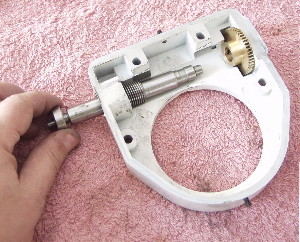

The picture to the left shows all of the components from the RA axis removed, cleaned and lubricated.