|

EQ6 Case Study and Shim Washer Considerations

| 1-Background |

There comes a moment in every technicians life when your own confidence and your ego can take a bit of a knock back. This was mine !

Now I like to think that its our failures that teach us the most and help to keep self confidence balanced at a point safely short of arrogance. The recent

rebuild of a Skywatcher EQ6 tested my patience and abilities to the limit and I felt it worth writing up the experience.

I have not written this up with any sense of smugness but rather that it gives people considering a mount rebuild some clues as to the possible issues and

how I overcame them in the hope it might save some of you time. It also taught me a lot about the engineering of these mounts which wasn’t discovered in the

original rebuild guide or the super-tune guide for reasons which will become apparent when you read through this case study.

It also shows how difficult a mount rebuild can be even when you have a lot of experience and a lot of tools to work with. It might also scare some people

who are convinced their mount is OK. If that’s you then move along because this part of my EQ6 guide might well give you sleepless nights.

Rather than rewrite the original EQ6 strip down guide with a lot of extra information, much of which wont be used in the average rebuild I have written

this as an addendum to be read with the main guide. Even if your rebuild goes smooth some of the information in this section will be worth a read.

| 2 – Initial Diagnosis and Mount History |

This EQ6 presented with a problem with its backlash and tracking. The mount would track reliably but when the user overrode tracking using a small

amount of slewing to correct for tracking errors the mount failed to maintain tracking afterwards and in some cases demonstrated unacceptable amount of backlash. Repeated manual slewing would cause the mount to eventually regain some reliability of tracking.

The mount was tested by me prior to rebuild and appeared to work quite well. The motors were relatively quiet with little gear noise and there was no

observable play in either axis.

The backlash problem appeared to me to be poor set-up on the motor/worm meshing. The mount was quite old with a history of at least one previous owner and as the mount showed some signs of having been opened up I suggested a full strip down and rebuild. Its impossible to estimate the age of this mount but I would imagine its at least 4 years old (ie manufactured around 2007).

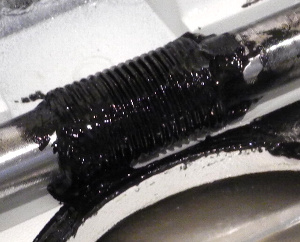

I felt it likely its overall assembly may be a bit poor (some of the early EQ6s did appear to suffer all manner of ill often associated by poor quality control at the

factory). If nothing else I felt sure the mount would be filled with the black goop that passes for lubricant in some of the Skywatcher mounts.

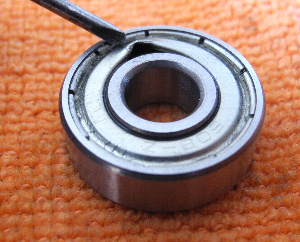

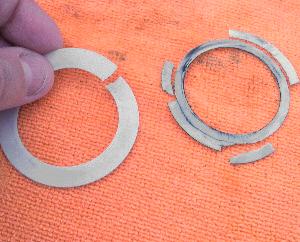

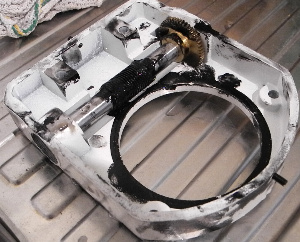

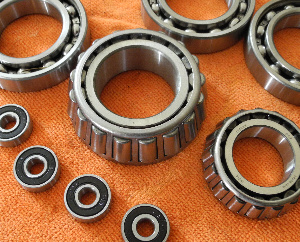

What followed was the strip-down from hell with a mount I christened the ‘demon’ mount for the huge amount of problems it was suffering internally. These included seized and broken bearings and every single internal shim washer being in a state of decay/destruction which was unexplainable.

This isn’t a complete strip down guide – just the edited highlights to show you how bad a mount can get while showing no outward signs of distress. I suspect given time the problems would have gotten worse.

| 3 – The Declination (DEC) Axis – Part I |

The bearing is shown above after extraction - only perhaps 50% of the damage was done during the extraction process showing what bad shape the bearing was in before I started work.

The shaft itself also suffered a small flaring at its tip from the metal to metal impact during removal. This prevented the DEC collar being refitted and had to be filed gently back to shape.

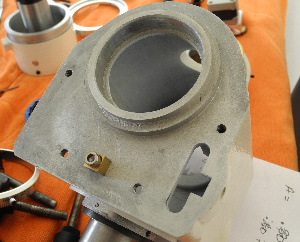

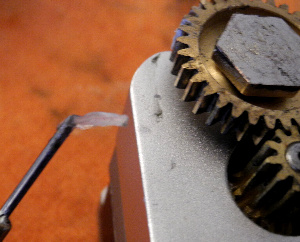

The top face where the worm carrier sits was cleaned and polished free of any paint to give the worm carrier a perfectly flat surface.

| 4 – A Little Detour in the DEC Axis Strip Down |

I found that the top of the DEC appeared to be fitted so tightly that it would be impossible to move without damaging the paintwork and opted for the approach of using a hammer to drive out the shaft.

| 5 – The Declination (DEC) Axis – Part II |

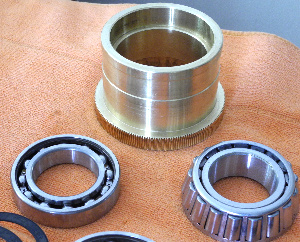

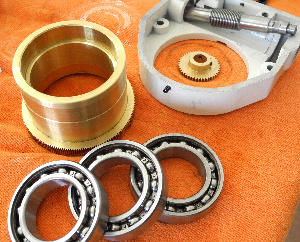

New worm roller end bearings were fitted as per the supertune guide.

| 6 – The Right Ascension (RA) Axis & Motors |

| 7 – EQ6 Shim Washer Considerations |

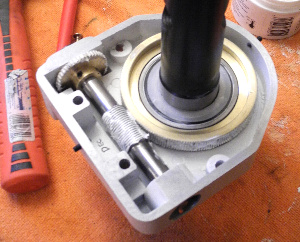

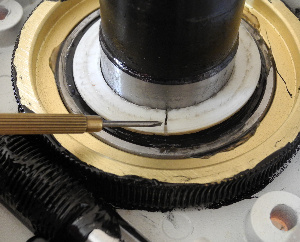

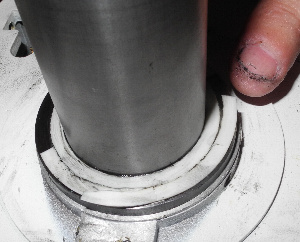

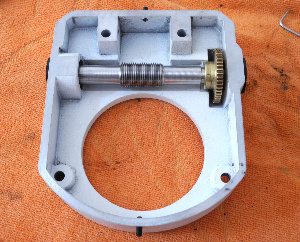

The shim washers control different aspects of the mounts fittings. The lower shim shown in the diagram above controls the height of the worm gear while the upper shim adjusts the height of the axis above the main mount block.

The upper shim shown in green controls the distance between the axis casing and the main worm carrier. This is easier to see with the DEC axis but the principle is identical for the RA axis. The axis casing and worm carrier are shown as the dotted line.

If the upper shim is too large it will create an unsightly gap between the scales and the mount. I corrected this by trial and error fittings of different sized shims until I was happy.

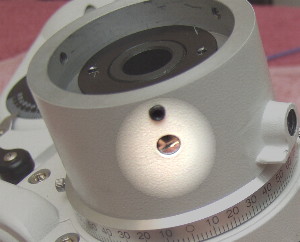

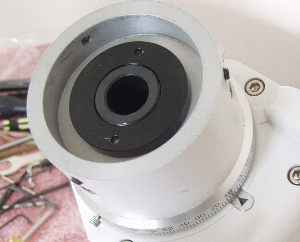

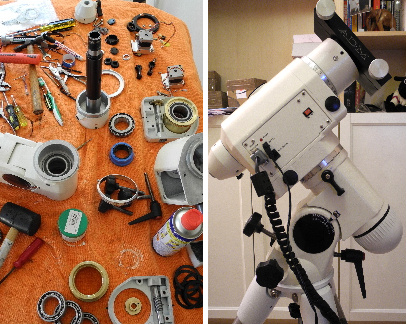

After rebuild the mount was thoroughly cleaned and any small chips in its paintwork were touched up with good quality enamel paint. When finally ready the mount looked as good as new only showing a slight yellowing of its paintwork. After suitable tuning the EQ6 in this part of the guide responded well. The mount was not quite as quiet as it had been running with the Synta grease (although still far better than most) but it was quite definitely better behaved. Both axis were smooth and free flowing. The DEC axis was never quite as free as I would have expected and hoped but I believe given time it will settle down in actual use. The bearings being filled with new grease may have contributed to this aspect. The mount was rebuilt with zero play in either axis and with a flawless backlash. When the mount comes to a halt a press on the slewing keys in either direction will set the mount moving immediately. Its tracking performance was tested against a stationary target and timed and was consistent and true. The pictures to the left show the mount in a complete state of disassembly and the mount after rebuilding and cleaning.

After rebuild the mount was thoroughly cleaned and any small chips in its paintwork were touched up with good quality enamel paint. When finally ready the mount looked as good as new only showing a slight yellowing of its paintwork. After suitable tuning the EQ6 in this part of the guide responded well. The mount was not quite as quiet as it had been running with the Synta grease (although still far better than most) but it was quite definitely better behaved. Both axis were smooth and free flowing. The DEC axis was never quite as free as I would have expected and hoped but I believe given time it will settle down in actual use. The bearings being filled with new grease may have contributed to this aspect. The mount was rebuilt with zero play in either axis and with a flawless backlash. When the mount comes to a halt a press on the slewing keys in either direction will set the mount moving immediately. Its tracking performance was tested against a stationary target and timed and was consistent and true. The pictures to the left show the mount in a complete state of disassembly and the mount after rebuilding and cleaning.