|

Lubrication and Reassembly of the Declination Axis

| Synta EQ6/Orion Atlas – Lubrication & Re-Assembling the Declination (DEC) Axis |

This procedure will guide you in re-assembling the EQ6/Atlas Declination axis and follows on from the stripping down and cleaning guide HERE.

GENERAL NOTE: Very little of the mount assembly requires brute force on tightening down components. They need to be firm but not so tight the threads pop.

Generally a light touch is required rather than brute force. Remember this is a precision piece of engineering and many of the fittings are aluminium so threads

can be easily stripped and ruined. As with the strip down process if you hit problems STOP and THINK. If something won’t fit theres a reason.

NOTE ON LUBRICATION: When this guide was originally written the accepted wisdom was that white lithium grease was an overall good lubricant. However

it would appear that standard white lithium grease may cause problems under some extremes of damp/temperature. All of the mounts I have rebuilt have been

done with white lithium that is stable and often mixed with a synthetic like Teflon or PTFE. It is best to consult the manufacturer on the quality of the product.

I find TF2 White Lithium grease with Teflon to work well.

Also I have seen questions asked about the density of grease used in packing the bearings. The grease should be forced into the bearings and should

provide good all round lubrication. You don’t need to pack the bearings solidly with grease.

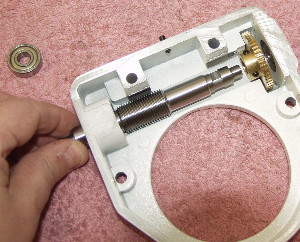

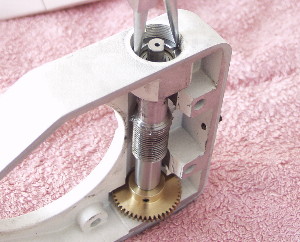

| Stage 4 – Re-assembling the Worm Carrier |

Note: You may need to use a driver to do this so use a small plastic handles screw-driver as shown in the picture. You can lightly tap the tip of the screwdriver with a hammer if the bearing is tight.

Note: It has been reported that some mounts will only accept the worm roller bearing from one direction (ie from the outside OR the inside of the carrier). If your having problems getting the worm into the carrier try coming from the other side.

Note: The motor gear must have one of its grub screws against the flat on the worm. One of the grub screws may be longer than the other. The long one goes against the flat. Both grub screws should be almost flush with the motor gear spindle when finished.

Note: There is a space between the motor gear and the widest part of the worm. It does not fit flush to the wide part of the worm gear.

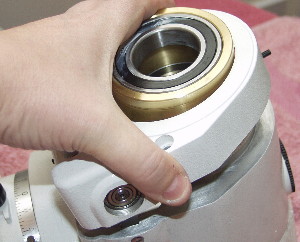

| Stage 5 – Re-assembling the Declination Axis |

Note: If you wish to carry out supertuning with replacement shim washers read the supertune guide HERE

Keep the main barrel element free of grease as this will impair the ability of the DEC scale to be locked when in use.