|

|

|

| Remove the polar scope cover. |

Remove the polar scope. You may need to grip it

with a wrench - if so wrap a cloth around

the

polar scope to protect it.

Alternately use some

masking tape to

protect the scope. |

Once

loosened simply unscrew the polar scope and

place it somewhere safe. |

| |

|

|

|

|

|

Remove the silver Phillips screw in the RA

lock lever. |

Remove the lock lever. You may need to

prise this

up by using the tip of a flat

bladed screwdriver and

gently twisting

the tip - see the Declination strip

down procedure for a picture of

this. |

Remove the brass RA lock bolt. You

may

need to use a small spanner or

pliers. Also remove

the small brass button beneath the lock bolt.

If

this is hard to do leave it -it can be removed easily

later in the

procedure. |

| |

|

|

|

|

|

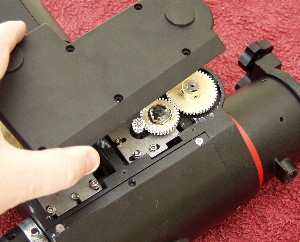

Unscrew the 6 Phillips screws around the

plastic

motor cover. |

Remove the motor cover and lay it aside

with its

screws. |

Slacken the two lock screws on the polarscope

mounting

plate. |

| |

|

|

|

|

|

Now remove the polarscope mounting plate by

unscrewing it. You can use either some snipe

nosed pliers to locate into the holes

OR a pair of

small/medium Phillips

screw drivers or similar OR

a pair of

small Allen keys. |

Loosen and remove the RA setting circles lock nut. |

Now

remove the RA setting circle. It should just

slip off. |

| |

|

|

|

|

|

Loosen the three lock screws set around the large

circular aluminium nut. |

Unscrew and remove the circular nut. You may

need a wrench to do

this - if so be careful of the

polar-scope mounting plate

threads.

Alternately use a

pair of flat bladed screwdrivers or

similar to apply

even pressure using the slots in

the nut - do this

with care.

Once

removed observe the tapered bearing. It may

come out at this point - if not it can be removed

easily after the following step. |

Remove the main RA Unit (right) from the base (left).

The Alt-Az base

contains a bearing which will most

likely not remove easily. Leave it in-situ but clean

the bearing and the Alt-Az internal

area and grease

the bearing face with

lithium grease.

Note: At this

point the small brass button for the

RA locking lever will be easy to

push out if you

were

unable to extract it earlier. |

|

|

|

|

|

|

Remove the tapered bearing from the

polarscope

end of the RA axis. |

Here's the RA axis removed - naturally it also has

the DEC axis as part of it.

Note the red washer on top

of the worm gear. Make

sure this is kept safe and is

replaced during

re-assembly. |

Unscrew the power panel. Its attached using two

Phillips screws. |

| |

|

|

|

|

|

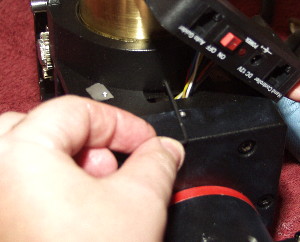

Shift the power panel slightly. Be careful not to

pull

too hard as it has wires which

connect to the main

board inside the RA

main housing. |

Loosen the worm engagement set-screw located

behind the power panel. |

Loosen the worm engagement set screw opposite

the power panel and above the Declination

scale. |

|

|

|

|

|

|

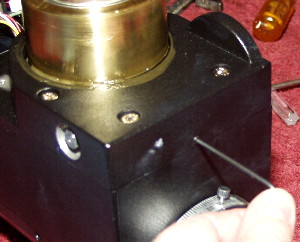

Remove the 3 cap headed bolts (silve

coloured)

from the worm carrier. |

Remove the worm carrier.. |

Remove the brass worm gear making sure

the small

red washer is kept aside. |

| |

|

|

|

|

|

Remove the roller bearings from the

brass worm

gear. They should slip out easily. |

|

|

| |

|

|