|

|

|

| Here is all the equipment ready for work. Emery cloth,

replacement bearings, Delrin shims, digital caliper and of course lithium

grease. |

This is a picture of the replacement worm roller end

shaft bearings. These are superior quality to the ones that the factory fit to

the mount.

Note: These

are supplied un-lubricated so require the seals to be gently pried away with a

very thin screwdriver and the bearing to be lubricated with the lithium grease

before replacing the seals. |

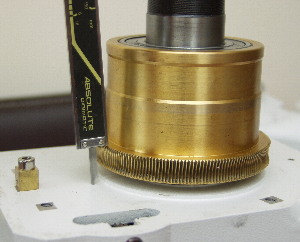

During rebuilding of the DEC and RA axis before

reassembly commences place the original factory teflon washer onto the face

plate and then place the worm gear onto the main shaft as in this picture.

Note: This is the same procedure for both the DEC and RA axis.

Measure the distance from the top of the worms gears face to the face of the

mount..... |

| |

|

|

|

|

|

......Here is the measurement in close up. From the top

of the gear teeth of the worm bearing to the face of the mount. Obviously when

you do this the digital caliper must be square to all faces.

Make a note of

this measurement which we shall call 'A' |

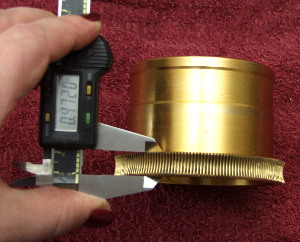

Now measure the depth of the worm gears machined teeth

and make a note - this is 'B' |

Measurements 'A' and 'B' are used to

calculate the centre of the worm gears teeth from the mount face. This is

achieved using the simple calculation above. The result of this calculation is

measurement 'F'.

You can however simply enter

your measurements into the calculator on this page and it will carry out the

shim size calculation for you. |

| |

|

|

|

|

|

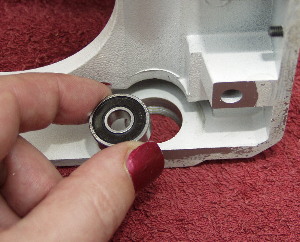

| Replace the worm roller end shaft bearing into the worm

carrier having first made sure it is suitably lubricated with lithium

grease. |

Measure the distance between the edge of the worm

carrier and the inside of the worm shaft end bearing. This will be a

measurement 'C' make a note of this. |

Finally measure the width of the worm roller end shaft,

this will be measurement 'D'. Make a note of this. |

| |

|

|

|

|

|

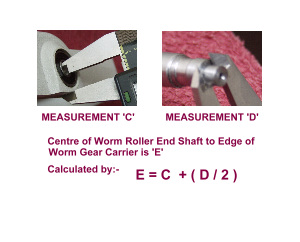

Measurements 'C' and 'D' are used to

calculate the centre of the worm rollers teeth from the base of the worm

carrier. This is achieved using the simple calculation above. The result of

this calculation is measurement 'E'.

You can however simply enter

your measurements into the calculator on this page and it will carry out the

shim size calculation for you. |

Now Simply Subtract F from E

and you have the shim size required.

Note: Sample

data from 2 other EQ6 Mounts is given in the tables below to give you some idea

of what sorts of numbers you should be seeing.

All of these calculations are done for you by just entering your

A, B, C and D measurements into the following

table |

Enter your A, B, C, D

measurements into this table to calculate the correct shim to place between the

worm gear and the bearing face.

Note: When you

click SUBMIT the page will reload and you will need to scroll down to the table

to see the result. |

| |

|

|

| Sample EQ6

Shim Values |

| A |

0.780 |

| B |

0.470 |

| C |

0.391 |

| D |

0.310 |

| E |

0.546 |

| F |

0.545 |

| Shim Size |

0.001 |

|

| RESULT = No shim required |

|

| Sample EQ6 Shim

Values |

| A |

0.776 |

| B |

0.461 |

| C |

0.390 |

| D |

0.311 |

| E |

0.546 |

| F |

0.540 |

| Shim Size |

0.000 |

|

| RESULT = No shim required |

|

| Sample EQ6

Shim Values |

| A |

0.775 |

| B |

0.476 |

| C |

0.390 |

| D |

0.313 |

| E |

0.547 |

| F |

0.537 |

| Shim Size |

0.010 |

|

|

RESULT = .010 Shim Required |

|

| To provide you with sample data these are the

measurements from an EQ6 DEC gear. Tolerances are fine so no shim is

required. |

Here is another sample from my own EQ6 RA gear. As you

can see tolerances are fine and no shim is required. |

Finally here is the data from an EQ6 RA gear which has

been poorly set up from the factory. A .010 shim is required. |

| |

|

|

|

|

|

Replace the gear ready for assembly with the correct

sized shim washer from your calculations.

Note: If the

original teflon washer from the factory is badly worn you can replace it with a

similar sized washer OR simply carry out your measurements with

NO washer in place and then use the appropriate sized Delrin shim

washer from the measurements and calculations |

POINTS ARISING....

You MAY find after rebuilding that the DEC is either loose and

can be pushed up and down OR that there is a gap between the DEC scale/collar

and the mount. This is a possible sign that you either have too much shim or

not enough. Read the notes below for more detail.You should also refer to the EQ6 Case Study guide for

shim washer considerations at the bottom of the page

HERE |

Finally you need to carry out worm tuning as per the EQ6

Strip Down and Rebuild Guide

HERE |