|

| 5 - Synta EQ6/Orion Atlas / Motor Engagement for RA and DEC

Axis |

This procedure will guide you

in setting up the EQ6/Atlas worm engagement and also aligning the motor gears

after the Declination and Right Ascension reassembly. These steps are best

carried out with the EQ6 head mounted onto

its tripod or some other type of stable base.

The worm setting

procedure - especially for the RA axis is very hit and miss and you will

probably need to go through it several time to find the 'sweet spot' where

there is both no play in the mount and the RA motor can turn the mount smoothly

with no motor stall or gear binding.

Play / tension in the mounts

axis are controlled by three elements. The worm carrier set screws, the end

float adjusters and, to a lesser extent, the motor engagement. If you are

having problems with a binding motor its best to slacken the motor away

altogether. Get a good setting on the worm carrier set screws and only then

tighten the motor back down. This symptom will show if all appears well UNTIL

the cap headed screws are tightened down. If this happens then the motor is

installed too tightly causing the motor gear and the worm gear to

bind. |

| |

| EQ6/Atlas Worm Engagement for DEC Axis |

|

|

|

| Loosen the DEC axis worm carriers four large silver cap screws

JUST ENOUGH so that the small set screws can move the worm

carrier. |

Loosen the DEC worm carrier upper set

screw

and........... |

.....Tighten the lower DEC worm carrier set screw just enough so that

you can feel some play in the axis.

Note: You should loosen and tighten these

screws

by approximately 1 quarter of a

turn each time. |

| |

|

|

|

|

|

| Now loosen

the lower set screw and......... |

.......Tighten the upper set screw JUST UNTIL

ANY PLAY

STOPS.

Note: You should loosen and tighten these

screws

by approximately 1 quarter of a

turn each time. |

Now tighten down the DEC worm carrier cap headed screws. Work around

the screws clockwise tightening a little each time until

fully

tight. |

| |

|

|

|

|

|

| The final

adjustment is to the worm end float adjuster. This is a slotted nut. It can be

turned using circlip pliers, snipe nosed pliers or two small screwdrivers with

fine blades. The worm float needs to be tight but not so tight that the mount

binds. Generally I start with the worm float being loose and then gradually

tighten it until the mount binds a little and then slacken it off. |

Run the mounts DEC motor a full 360' to make sure there is no

binding at any point in the cycle.

If binding occurs you will need to

readjust the set screws. This can be a long process to get the perfect balance

between no play in the axis and smooth motor running. |

Reinstall the worm end float cover. |

|

|

|

|

| EQ6/Atlas Worm Engagement for RA Axis |

|

|

|

| Loosen the RA worm carriers four large silver cap screws JUST

ENOUGH so that the small set screws can move the worm carrier. |

Loosen the RA worm carrier upper set

screw

and...........

|

.....Tighten the RA worm carrier lower set screw just

enough so that you can feel some play in the axis.

Note: You should loosen and

tighten these screws

by approximately 1

quarter of a turn each time |

| |

|

|

|

|

|

| Now loosen the lower set screw and......... |

.......Tighten the upper set screw JUST UNTIL

ANY

PLAY STOPS.

Note: You should loosen and

tighten these screws

by approximately 1

quarter of a turn each time |

Now tighten down the RA worm carrier cap headed screws.

Work around the screws clockwise tightening a little each time until

fully

tight. |

| |

|

|

|

|

|

| The final adjustment is to the worm end float adjuster. This is a

slotted nut. It can be turned using circlip pliers, snipe nosed pliers or two

small screwdrivers with fine blades. The worm float needs to be tight but not

so tight that the mount binds. Generally I start with the worm float being

loose and then gradually tighten it until the mount binds a little and then

slacken it off. |

Run the mounts RA motor a full 360' to make sure there

is no binding at any point in the cycle.

If binding occurs you will need to

readjust the set screws. This can be a long process to get the perfect balance

between no play in the axis and smooth motor running. |

Reinstall the worm end float cover. |

|

|

|

|

|

|

If you are

only adjusting the worms on the EQ6 and are curious about how they work these

diagrams may help.

The set screws that you adjust bear againts two brass

blocks inside the mount under the worm carriers. The diagram above shows the

layout of the running gear inside the worm carrier. |

As you tighten the lower set screw the screw pushes against the block

thats secured to the mount. The set screw forms part of the worm carrier so as

you tighten the set screw (small blue arrow) the carrier is forced towards the

block (large blue arrow). In this case as you tighten the lower set screw the

worm is pulled away from the ring gear. This is the firts step in tun ing the

worm gear. |

As you tighten the upper set screw (small red arrow) the same process

occurs. The worm carrier is forced backwards towards the set screw (large red

arrow) and as you can see the worm itself is now pulled into contact with the

ring gear.

Its

essential when you play with the set screws that you always slacken the

opposing set screw off to prevent damage to the mount. |

| |

|

|

|

| EQ6/Atlas Motor Gear Removal and Adjustment |

As part of the

complete strip down guide I removed the motors and the motor control board from

this mount. This isn't really necessary for a conventional strip down but given

the mounts history of poor periodic error performance I needed to make sure the

motor gear was OK and that there were no problems.

In fact the motor

gear, like the rest of the mount, was suffering almost no lubrication. This

step can be necessary after a rebuild to reseat the motors. Cleaning up the

over painting on the worm carriers can reduce the distance between the gears

enough to cause the gear works to become too tight with the result that the

motors will bind and stall.

|

|

|

|

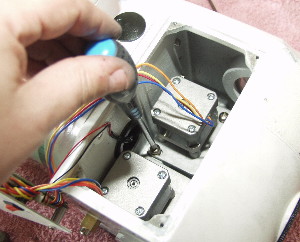

| Remove the 4 outer screws around the EQ6/Atlas control

panel. |

Gently pull the control panel away, revealing the motor control

board. You can either disconnect the motors from the main board or leave alone

and extract all of the motors and control board as one unit.

CAUTION Take suitable

static precautions as the motor boards on these mounts are reputed to be very

fragile. |

Remove the two screws from each motor and be careful not to lose the

washers. |

| |

|

|

|

|

|

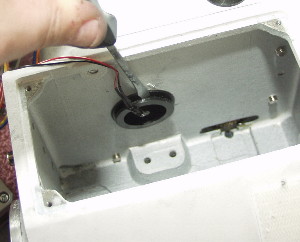

| Gently ease the motor away and extract it. You will need to do this

for each motor. |

Using a fine bladed screwdriver prise the polarscope illuminator away

from the mount. |

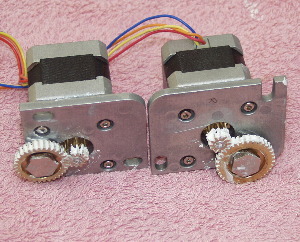

The motors on this mount showed little lubrication. Their gears were

cleaned with a little alcohol on a cotton bud and then regreased using white

lithium grease. |

| |

|

|

|

|

|

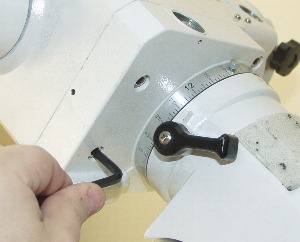

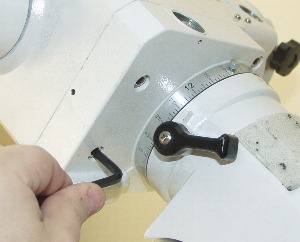

| Reinstall the motors. Because the gearworks are hidden in the EQ6 at

this stage its not possible to gauge pressure on the motors. I would advise

gentle pressure against the motor towards the worm gear as you replace the

fixing screws for the motor. |

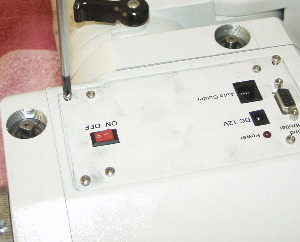

Replace the polarscope illuminator. |

Replace the motor control board/control panel and replace the outer

screws. |

| |

|

|

|

|

| EQ6/Atlas Altitude Movement |

The mount used for the

rebuild in this guide had no problems with its altitude bearings. Altitude

bearing problems will show when the mount will rock in its altitude no matter

how tight the altitude adjusters are locked down.

As the process of adjusting

these can be destructive to the mounts trim and no problems were observed with

this mount these were left alone. Consult the HEQ5 guide

HERE for instructions as to

how to adjust these. The HEQ5 and EQ6 are similar in this

respect.

|

| Back to the EQ6/Atlas Rebuild Guide

Main Page |

| |

|

|