|

|

|

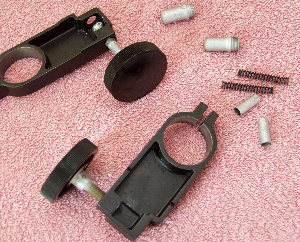

| The first stage of rebuilding was the RA and DEC

clutches and slow motions. Here are the parts laid out after cleaning and

painting. |

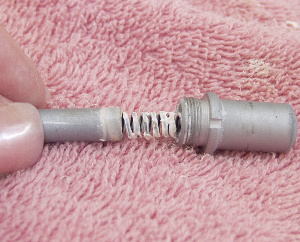

Pack the spring pusher assemblies with lithium grease

and make sure the spring itself is well greased. |

Insert the spring into the piston at one end and the

cylinder at the other end. |

|

|

|

|

|

|

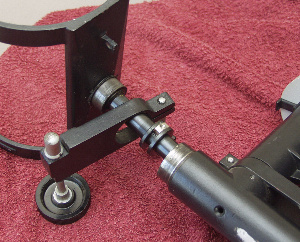

| Now insert the assembled spring pusher and piston

assembly. This is easier if you unwind the slow motion knob as far out as

possible. |

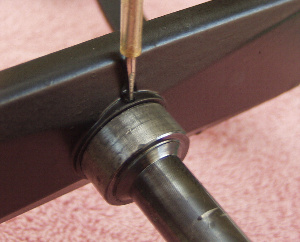

Tighten the spring assembly cylinder using some grips.

Its best to place a soft cloth between the grips and the component for this to

avoid the metal finish being damaged. |

Finally dab a little grease onto the slow motion

controls threads and wind it in to the mount to fully lubricate the

threads. |

|

|

|

|

|

|

| A tiny smear of grease should be added to the inner

surfaces of the clutch assembly where it mates with the mount. Too much will

cause the mount to slip when locked. No grease at all will make the mount bind.

You need just very thin layer of grease here. |

Now reassemble the mount cradle/saddle to the DEC

spindle. Screw this into place and then tighten down the small lock screw. Do

not overtighten this. |

Replace the main DEC housing into the mounts altitude

fitting. Note that the DEC bearing faces were masked during painting. |

|

|

|

|

|

|

| Replace the main altitude bearing spindle. |

Replace the three small screws in the altitude bearing

spindle. |

Replace the lower nut into the altitude assembly. |

|

|

|

|

|

|

| Replace the steel washer onto the main altitude

spindle. |

Replace the altitude locking lever and tighten

down. |

Replace the RA slow motion/clutch assembly over the DEC

main housing. |

|

|

|

|

|

|

| Replace the small square nut on the RA spindle between

the two collars. In this picture this has been greased. |

Grease the RA spindle on its bearing faces. |

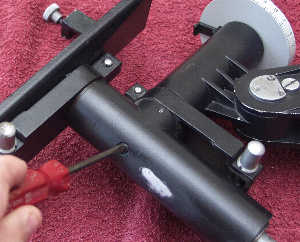

Now insert the RA spindle into the mount making sure

that the tag on the RA casing mates up with between the spring pusher/piston

and the slow motion control. You will find this easier by unwinding the slow

motion control as far as possible and using a thin bladed screwdriver to press

open the spring pusher. |

|

|

|

|

|

|

| Replace and tighten down the screw that locates to the

small square nut on the RA spindle. |

Replace the RA lock knob. |

Apply a small smear of grease to the inner face of the

DEC housing. |

|

|

|

|

|

|

| Replace the small square nut on the DEC main

spindle. |

Place the DEC spindle into the DEC slow

motion and clutch assembly and insert it into the mount. Make sure the spindle

is greased on its bearing faces prior to assembly.

Note this picture was taken in the strip down phase as the rebuild

picture was faulty. |

Use the same technique to fit the DEC slow motion and clutch as you

used with the RA assembly to make sure the tab on the cradle is mated correctly

to the slow motion controls. Now replace the screw that locates to the small

square nut on the DEC spindle.

Note

this picture was taken in the strip down phase as the rebuild picture was

faulty. |

| |

|

|

|

|

|

| Replace the DEC lock knob. |

Replace the DEC index scale marker but do not tighten

the screws down yet. |

Replace the DEC setting circle. |

| |

|

|

|

|

|

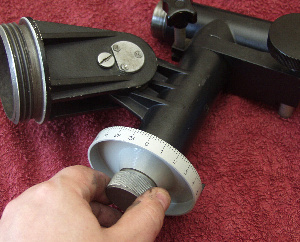

| Replace the DEC knurled spindle main nut. Once this is

done you can adjust the index marker so that it is close (but not in contact

with) to the setting circle and tighten down the screws holding the index

marker to the mount. |

Replace the RA index scale marker. |

Replace the RA setting circle |

| |

|

|

|

|

|

Replace the RA knurled main spindle

nut.

Note this picture was taken in

the strip down phase as the rebuild picture was faulty. |

Replace the setting circle locking nuts on both setting

circles. |

The finished article looking better than new. New felts

have been adding to the tube rings and the mount looks and works 100% better

that before. |

| |

|

|