|

| 5 - Synta HEQ5 -Worm / Motor Engagement for RA and DEC

Axis |

This procedure will guide you

in setting up the HEQ5 worm engagment and also aligning the motor gears after

the Declination and Right Ascension reassmbly. These steps are best carried out

with the HEQ5 head mounted onto its tripod

or some other type of stable base.

The worm setting procedure -

especially for the RA axis is very hit and miss and you will probably need to

go through it several time to find the 'sweet spot' where there is both no play

in the mount and the RA motor can turn the mount smoothly with no motor stall

or gear binding. |

| |

| Worm Engagement for DEC

Axis |

|

|

|

| Loosen the DEC axis worm carrier three large silver cap screws

JUST ENOUGH so that the small set screws can move the worm

carrier. |

Loosen the DEC worm carrier upper set

screw

and........... |

.....Tighten the lower DEC worm carrier set screw just enough so that

you can feel some play in the axis.

Note: You should loosen and tighten these

screws

by approximately 1 quarter of a

turn each time. |

| |

|

|

|

|

|

| Now loosen

the lower set screw and......... |

.......Tighten the upper set screw JUST UNTIL

ANY PLAY

STOPS.

Note: You should loosen and tighten these

screws

by approximately 1 quarter of a

turn each time. |

Now tighten down the DEC worm carrier cap headed screws. Work around

the screws clockwise tighetning a little each time until

fully

tight. |

| |

|

|

|

|

| At this point return to the DEC Assembly Guide or simply replace the Motor

Cover. |

|

| Remove the

motor cover and check that the motor gears can easily move the axis by manually turning them by hand or using the

mounts motors. |

Run the mounts DEC motor a full 360' to make sure there is no

binding at any point in the cycle.

If binding occurs you will need to

readjust the set screws. This can be a long process to get the perfect balance

between no play in the axis and smooth motor running. |

|

| |

|

|

|

| Worm Engagement for RA

Axis |

|

|

|

| Loosen the RA worm carriers three large silver cap screws JUST

ENOUGH so that the small set screws can move the worm carrier. |

Loosen the RA worm carrier upper set

screw

and...........

Note:

You will have to remove the power panel to get axis to the upper RA set screw.

The panel is retained by two Phillips screws. |

.....Tighten the RA worm carrier lower set screw just enough so that

you can feel some play in the axis.

Note: You should loosen and

tighten these screws

by approximately 1

quarter of a turn each time |

| |

|

|

|

|

|

| Now loosen the lower set screw and......... |

.......Tighten the upper set screw JUST UNTIL

ANY PLAY

STOPS.

Note: You should loosen and tighten these

screws

by approximately 1 quarter of a

turn each time |

Now tighten down the RA worm carrier cap headed screws. Work around

the screws clockwise tighetning a little each time until

fully

tight. |

| |

|

|

|

|

At this point return to the RA Assembly Guide or simply replace the motor cover

and the power panel using the Phillips screws.

Take care when replacing the power panel

not to trap any wires. |

|

| Remove the motor cover and check that the motor gears can easily move

the axis by manually turning them by hand

or using the mounts motors. |

Run the mounts RA motor a full 360' to make sure there is no

binding at any point in the cycle.

If binding occurs you will need to

readjust the set screws. This can be a long process to get the perfect balance

between no play in the axis and smooth motor running. |

|

| |

|

|

|

| End Float

Adjustment |

|

|

|

Remove the soft rubber covers to reveal the end

of the worm shaft

and float adjuster. |

Loosen the float adjusted using either a small

jewellers

screwdriver or a small allen key to locate into the adjusters slots. You

should feel the some play in the axis. Now tighten the float adjuster down

until any play disappears. The float adjuster should be in contact with the

worm bearing but not overtight or else the axis will 'bind' |

Replace the rubber worm float covers |

|

|

|

|

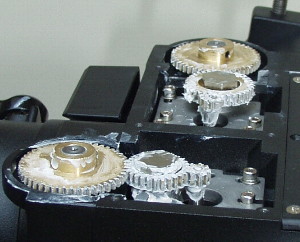

| Motor Gear

Adjustment |

|

The

HEQ5 Motor gears should all be flush with each other as shown in the picture to

the left. The gears should be closely fitted but not pressed together too tight

to prevent excessive gear wear.

REMEMBER one of the

gear set screws must be against the flat of the worm spindle.

The

gears in my mount are liberally coated with Lithium grease to reduce wear and

also to muffle running noise. |

|

|

|

|

|

|

| Back to the main page

HERE |

| |

|

|