|

|

|

Remove the silver Phillips screw in the declination

lock

lever. |

Remove the lock lever. You may need to prise

this

up by using the tip of a flat

bladed screwdriver and

gently twisting

the tip. |

Remove the brass declination lock bolt.

You may

need to use a small spanner or

pliers to loosen it. |

| |

|

|

|

|

|

Remove the small 'button' if this didn't

come out

with the lock bolt. If you cant

get this out don't

worry it can be removed at a later stage. |

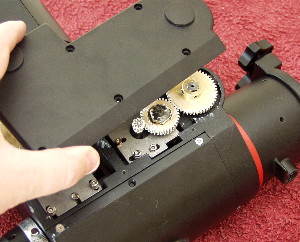

Unscrew the 6 Phillips screws around the

plastic

motor cover. |

Remove the motor cover and lay it aside

with its

screws. |

| |

|

|

|

|

|

Loosen the 3 set screws in the dovetail

carrier.

These are located closest to

the dovetail. |

Remove the dovetail carrier. You may

have to twist

it back and forth and

gently rock it off.

Note: You

can at this point remove the

counterweight bar by pushing it

up and out of the

DEC axis after

removing the knurled safety nut on

the

end. |

Loosen the deep set screws in the

Declination

barrel. On my mount these

screws do not hold

anything as the

barrel is a single piece of machined

metal. But some mounts are two piece. |

| |

|

|

|

|

|

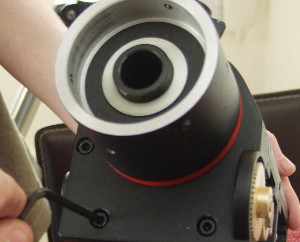

Unscrew and Remove the round 'nut' at

the top of

the Declinationshaft. You can use

either a pair of

Allen keys, two small Phillips drivers or a pair of

strong snipe nosed

pliers as shown here. At this

stage you may be able to remove

the Declination

barrel if its in two pieces (mine appears to be a

single piece) . If not don't

worry and

carry on - it will

be freed up later. |

Loosen the three set screws in the

counterweight

collar. |

Unscrew the counterweight collar. It may

be quite

tight. |

|

|

|

|

|

|

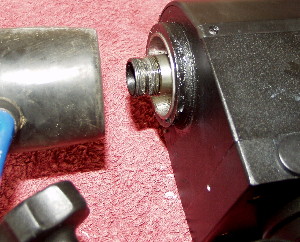

Remove the tapered bearing behind the

counter-

weight collar. Mine showed very

little lubrication as

can be seen

here. |

Remove the Declination scale from the

counter-

weight collar. If the mount is

to be GoTo apply a

small smear of grease

otherwise clear any grease

from the

collar. |

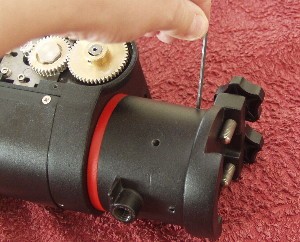

Loosen the worm adjustment set screw

located just

in front of the power

panel. This will need to be

loosened a

lot. |

| |

|

|

|

|

|

Loosen the opposing worm adjustment set

screw

opposite the screw on the previous

step - as shown

above. This will also

need to be slackened off a lot. |

Remove the three cap head bolts. They

are usually

silver coloured located on

the top of the worm

carrier. |

Now lightly tap the end of the

Declination shaft

which is exposed

(after removing the counterweight

collar) with a rubber mallet or block of wood. |

|

|

|

|

|

|

Slide out the Declination shaft and set

it aside.

On my unit the Declination barrel

refused to budge

from the main shaft

- this isn't important.

Note: If you had been unable to get the lock

lever

'brass button' earlier - it will now be easy to remove

from inside the Dec barrel. |

Remove the brass Declination gear

carefully. |

Take care to note and remove the small

clear

washer andremember to replace it

later. |

| |

|

|

|

|

|

| Remove the worm drive

carrier. |

Remove the roller bearing from the main

housing.

My bearings showed poor

lubrication from the

factory. |

Remove the two roller bearings from the

Declination

gear. The gear showed swarf

contamination from the

manufacturing

process in my mount. |

| |

|

|